00 +

Years of Experience

Raw material is decided by the designer based upon application. Material to be used is inspected and then proper storage location need to be identified.

Mostly casting and forging are used in this stage. Other methods may also be used:

1. Cold Forging

2. Hot Forging

Inspection of Cold Forged Material by Vernier Callipar and other instrument as per Client requirement.

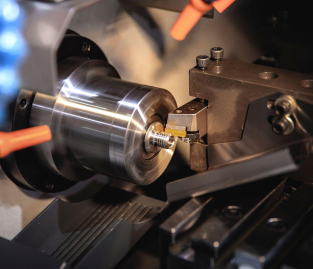

After finishing process, thread rolling is done with two dies. One is stationary and another is a moving die which actually exerts pressure on the bolts and forms threads.

Heat treatment is done after machining to make the fastners stronger. Hardening & tempering operations are followed.

After thread rolling, bolts and screw fastners are coated in order to prevent rust and corrosion. A fine example of bolt coating is geomet coating in bolts.

Our delivery service ensures prompt and reliable transportation of your products, guaranteeing timely arrivals and efficient distribution.

Established in the year 2008, We, Shivdas Fastners, are one of the illustrious names occupied as Manufacturers, Exporters, Suppliers. We offer wide range of:

With our outstanding service and competitve pricing, count on us to give you great value and significantly reduce your procurement expenses.

We will get you the right answers and the right parts, right now. And meet your needs with a smile.

The parts we stock for you are always close by and available for same day delivery or pick up.

Years of Experience

Products Range

Happy Customers

Skilled Employees